Images, video and audio from this Web site are provided without login for the purpose of editorial use only.

You must contact media@ford.com to obtain approval for advertising, marketing or other commercial users.

Ford Media Center

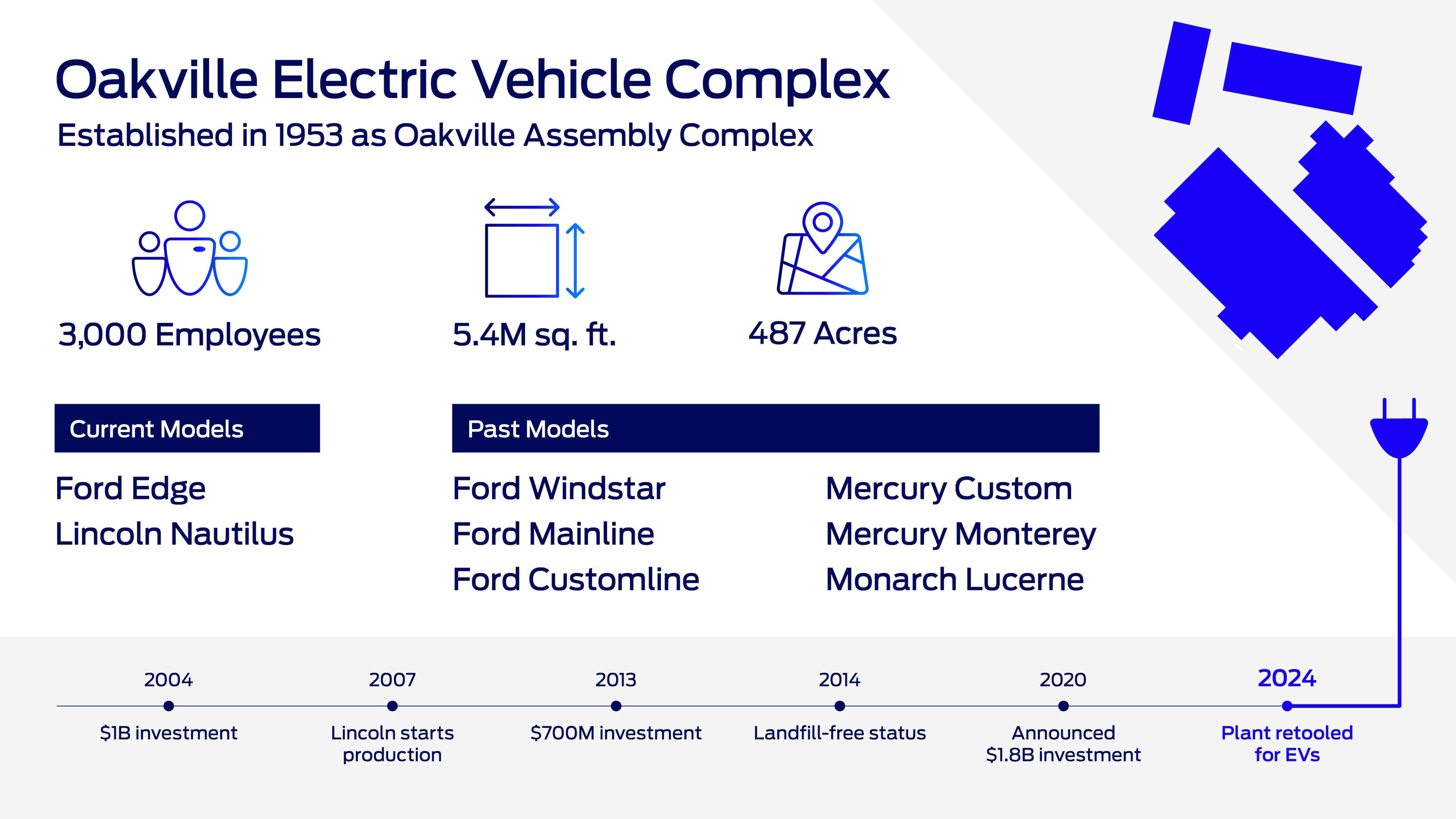

OAKVILLE, Ont., April 11, 2023 – Ford Motor Company is investing C$1.8 billion in its Oakville Assembly Complex to transform it into a high-volume hub of electric vehicle manufacturing in Canada – a key part of the company’s plan to scale production of electric vehicles and make them more accessible to millions of customers.

The campus, to be renamed Oakville Electric Vehicle Complex, will begin to retool and modernize in the second quarter of 2024 to prepare for production of next-generation EVs. This marks the first time a full-line automaker has announced plans to produce passenger EVs in Canada for the North American market.

“Canada and the Oakville complex will play a vital role in our Ford+ transformation. It will be a modern, super-efficient, vertically integrated site for battery and vehicle assembly. I’m most excited for the world to see the incredible next-generation electric and fully digitally connected vehicles produced in Oakville.”

-Jim Farley, Ford president and CEO

The investment allows Ford to repurpose and transform existing buildings into a state-of-the-art facility that leverages Ford of Canada’s skilled and experienced workforce. Ford is taking a diverse strategic approach to transforming its industrial system to expand EV production: building new greenfield sites and also transforming existing manufacturing sites like in Oakville and Cologne, Germany.

“Ford’s commitment to invest in OAC retooling and upskilling signals a bright future for Canadian EV production and for Canadian auto sector employment,” said Lana Payne, Unifor National President. “The transformation of the Oakville plant is an important step towards a stronger industry and testament to the hard work, skills and dedication of our Unifor Oakville Assembly Complex members.”

“Ford of Canada has been a leader in the country’s auto industry since it was founded 119 years ago, driven by hard-working, dedicated employees,” said Bev Goodman, president and CEO, Ford of Canada. “As the top-selling auto brand in Canada for 14 straight years, the successful transition to EV production in Oakville will help deliver stable Canadian employment with the opportunity to build the new skills and expertise to drive Ford and the industry forward.”

The current 487-acre Oakville site includes three body shops, one paint building, one assembly building. The transformed campus will feature a new 407,000 square-foot on-site battery plant that will utilize cells and arrays from BlueOval SK Battery Park in Kentucky. Oakville workers will take these components and assemble battery packs that will then be installed in vehicles assembled on-site.

“Ford’s transformation from gas to electric vehicles is well underway. Once complete, the Oakville Electric Vehicle Complex will secure thousands of well-paying jobs for our hard-working Canadian autoworkers and boost the competitiveness of Canada's auto sector. The partnership between Ford and Canada helps to position us as a global leader in the EV supply chain for decades to come,” said François-Philippe Champagne, Minister of Innovation, Science and Economic Development of Canada.

In addition to the Oakville Electric Vehicle Complex upgrades, Ford also has announced:

"Ford’s investment in retooling its Oakville plant will support thousands of good paying jobs and is an important milestone in our plan to become a leader in the electric vehicle revolution,” said Premier Doug Ford. “Together, with our industry and union partners, we’re building up a world class, home grown electric vehicle supply chain, from mining to manufacturing, so that the vehicles of the future are built right here in Ontario, by Ontario workers.”

Added Vic Fedeli, Ontario’s Minister of Economic Development, Job Creation and Trade:“Ford’s investment to transform its Oakville facility to manufacture passenger electric vehicles will strengthen our end-to-end EV supply chain and help ensure that the vehicles of the future are built here in Ontario. With our plan to build a strong Ontario, we continue to create the right conditions for businesses and workers to succeed now and for generations to come.”

# # #

Ford Motor Company (NYSE: F) is a global company based in Dearborn, Michigan, committed to helping build a better world, where every person is free to move and pursue their dreams. The company’s Ford+ plan for growth and value creation combines existing strengths, new capabilities and always-on relationships with customers to enrich experiences for customers and deepen their loyalty. Ford develops and delivers innovative, must-have Ford trucks, sport utility vehicles, commercial vans and cars and Lincoln luxury vehicles, along with connected services. The company does that through three customer-centered business segments: Ford Blue, engineering iconic gas-powered and hybrid vehicles; Ford Model e, inventing breakthrough electric vehicles along with embedded software that defines exceptional digital experiences for all customers; and Ford Pro, helping commercial customers transform and expand their businesses with vehicles and services tailored to their needs. Additionally, Ford provides financial services through Ford Motor Credit Company. Ford employs about 174,000 people worldwide. More information about the company and its products and services is available at corporate.ford.com.